Spyderco Military 2 Knife Black G10, Satin CPM S30V by Sal, Eric Glesser (C36G2)

- Military 2 Black G-10, Plain, the second edition, continuously produced for over 25 years, of Spyderco's iconic Military model. Stronger, intuitive Compression Lock, reinforced steel liners, same aggressive look and excellent utility!

Military 2 Black G10, Plain the second edition, continuously produced for over 25 years, of Spyderco's iconic Military model. Stronger, intuitive Compression Lock, reinforced steel liners, the same aggressive look and excellent utility! A demonstration of the craftsmanship of father and son knifemakers Sal and Eric Glesser!

One of Spyderco's most recognizable knives, it has gained a slew of followers both in the military and among civilian consumers. The full-size handle makes it easy to use the folder with gloves as well as for people with large hands. The reinforced, open design makes it easy to clean and adjust the folder. Manufactured at the Spyderco factory in the USA (Golden, Colorado).

CPM S30V - one of the best knife steels, corrosion resistant, mechanical stress resistant American CPM S30V martensitic powder steel with added carbon, chromium and vanadium with a hardness of 58-59 HRC. Developed by Dick Barber of Crucible Industries in collaboration with knife maker Chris Reeve to offer the best combination of strength, abrasion and corrosion resistance. Manufactured by US Crucible Industries according to the Crucible® Particle Metallurgy (CPM) process. The CPM process yields a very homogeneous, high-quality steel with excellent dimensional stability, grindability and ductility compared to steels produced by conventional methods. The alloy contains 1.45% carbon (C) and a significant admixture of vanadium carbides 4.0% (V) and chromium 10.5% (Cr). Thanks to its properties, it holds sharpness for a very long time and provides high corrosion resistance.

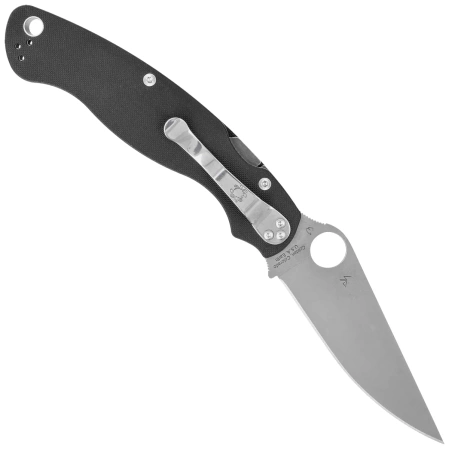

Compression-Lock - (similar to Liner-Lock) Blade locking mechanism patented by Spyderco (made in USA). Extremely durable, it provides extreme strength and ease of use. Located on the back of the Handle, it protects the knife from inadvertent locking. When releasing the lock, the fingers are not in the path of the folding Blade.

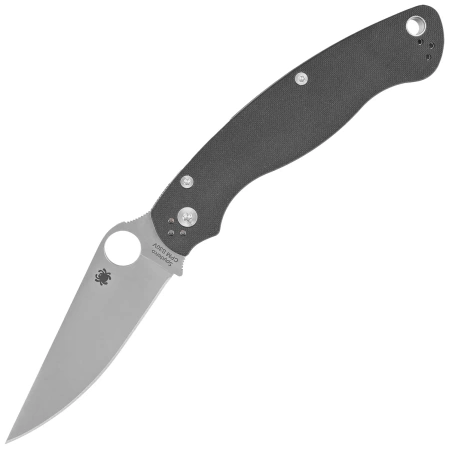

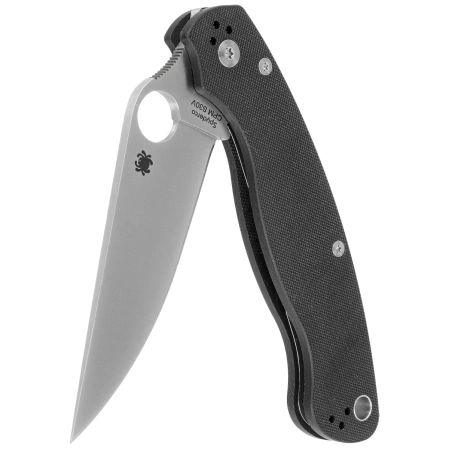

Blade - modified Clip Point profile with enlarged 14 mm SpyderHole notch (Spyderco patent) for quick opening of the knife also with a glove, enlarged thumb ramp with notches (spine jimping), which helps control the large blade. Index Finger Choil (notched profiled undercut for the index finger between the Handle and the cutting edge), prevents the folder from sliding in the hand when making powerful cuts. The Plain smooth blade, combined with the Full Flat Grind, gives excellent cutting edge geometry and extreme cutting performance.

Handle - full-length, contoured, covered with lightweight, non-slip textured grips made of durable, temperature- and chemical-resistant G-10 composite (pressure-pressed fiberglass with synthetic resin) screwed to steel liners. The folder is equipped with a screw-on metal clip with 4-way clip positions (up/down, right/left). In the rear part of the grip an enlarged hole (lanyard hole) for pulling a lanyard or safety line.

Technical data:

Product number: C36GP2

Product name: Military 2 Black G10, PlainEdge

Overall length: 242.0 mm / 9.51"

Blade length: 102.0 mm / 4.0"

Blade thickness: 3.7 mm / 0.145"

Handle length: 140.0 mm / 5.51"

Handle thickness: n.d.

Weight: 122.0 g / 4.3 oz

Blade material: CPM S30V

Blade hardness: n.d.

Blade grind: Full-Flat

Blade finish: Satin

Handle material: G10

Handle finish color: Black

Backspacer material: Stainless Steel

Backspacer color: Gray

Clip: 4-position ambidextrous

Clip material: Stainless Steel

Pivot mechanism: Washers (washers)

Locking mechanism: Compression Lock

Opening method: Manual, thumb hole

Additional accessories: None

Designer: Sal Glesser & Eric Glesser

Brand: Spyderco

Manufacturer: Spyderco, U.S.A.

Country of Origin: U.S.A.

Developed by: Sharg® company

Przeczytaj!

This product is intended for use only by adults with knowledge and experience in handling sharp cutting tools. Improper use of the knife can result in serious injuries. The blade is extremely sharp and can easily cut through skin and tissue; therefore, extra caution should always be exercised while cutting, and hands should be kept away from the cutting edge. To prevent the knife from slipping, it is recommended to cut on a stable, non-slip surface and avoid excessive force, which may cause uncontrolled blade movement.

Leaving the knife on the edge of a table, countertop, or in easily accessible places—especially where children are present—poses a significant safety risk. The knife should always be properly secured after use, ideally by placing it on a stable surface or storing it in designated knife blocks, protective sheaths, or magnetic strips. The knife should never be used for tasks it is not designed for, such as opening cans or prying objects, as this can damage the tool and lead to dangerous accidents.

A dull blade increases the risk of injury, as it requires more force and is more likely to slip from the material being cut. Therefore, it is essential to sharpen the knife regularly to maintain optimal sharpness. Additionally, proper cleaning and drying of the knife are necessary to prevent corrosion and bacterial growth. Periodic inspection of the handle and blade is recommended to check for cracks, chips, or looseness. If any damage is detected, the knife should be repaired or replaced immediately.

When using the knife, focus solely on the task at hand—avoid talking on the phone, watching television, or other distractions while cutting. Ensure proper lighting in the workspace for better visibility and control. Please note that some countries or regions have laws restricting the ownership and carrying of knives. Before purchasing or using this knife, verify that its use is legal in your location according to applicable regulations.

Following these safety guidelines will help ensure safe and effective knife use, minimizing the risk of accidents and extending the lifespan of the tool.