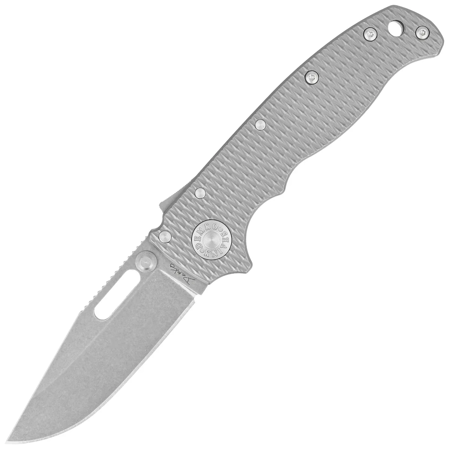

Demko Knife AD20.5 Clip Point Milled Titanium, Stonewashed CPM 20CV by Andrew Demko (205-20CV-TI-TEX-CP)

- Demko AD20.5 Clip Point Milled Titanium, Stonewashed CPM 20CV rugged, powerful EDC folder designed for hard work. Designed by Cold Steel's longtime designer, Andrew Demko. Its Shark-Lock™ locking mechanism is recognized as the strongest in the world!

AD20.5 Clip Point Milled Titanium, Stonewashed CPM 20CV, the result of years of work and experience of Andrew Demko, a long-time designer at Cold Steel. A compact folding knife that was designed for the toughest tasks. A real tool, characterized not only by its robustness and power, but also by its unique design. Ergonomic Handle, made of titanium and Blade made of CPM 20CV, one of the best powder steel used in knives today. One of the most important elements of the knife is its lock. Shark-Lock™ is an innovative mechanism that is considered one of the strongest in the world.Thanks to it, the knife is not only safe to use, but also gives you the confidence that it will stand up to even the toughest tasks.This is an exceptional example of a compact EDC (Every Day Carry) knife, an excellent choice for anyone looking for a reliable everyday tool.

Andrew Demko - owner and founder of Demko Knives, first started forging chisels in 1988, when he was in seventh grade. He immediately realized it was his passion and began forging knives almost immediately. Like many blacksmiths, Andrew began his journey in the garage, honing blade shapes and sharpening them on a small grinder. Andrew's passion for engineering and attention to detail was noticed by the well-known Cold Steel company. At Cold Steel, Andrew developed some of the most innovative and powerful locking mechanisms in the industry. The legendary Tri-Ad Lock, Scorpion Lock, and most recently the one-handed operator's dream - the Shark-Lock.

CPM 20CV - one of the best tool steels, American premium martensitic stainless steel. Produced by US Crucible Industries using the particle metallurgy / Crucible® Particle Metallurgy (CPM) method. The CPM process creates a very homogeneous, high-quality steel with excellent dimensional stability, grindability and ductility compared to steels produced by conventional methods. Designed to provide better wear resistance while maintaining corrosion resistance at the highest level. This super steel is comparable to Bohler's M390 steel or Carpenter's CTS-204P. According to some knife manufacturers, 20CV is the best of these three steels in terms of edge retention. It consists of 1.9% carbon (C), 20.0% chromium (Cr), 4.0% vanadium (V), 1.0% molybdenum (Mo) and 0.6% tungsten (W). The high percentage of chromium with a touch of molybdenum makes 20CV one of the best high-end corrosion-resistant steels.

Shark-Lock™ mechanism is located on the back of the knife and is operated by a ramp-like "flipper." Opening the blade causes the spring-driven locking arm to move up and then into a notch in the shank, placing it under the locking pin. Uniquely, the locking mechanism moves forward and backward while moving up and down at the same time. This allows for an increase in the size of the blade contact area, providing better mechanical strength in a specific area. And since the drive spring that moves the locking element upward to the locked position is located in the locking arm itself, it will not be exposed to dirt and debris.

Blade - Clip Point type, finished with a scratch-masking bath of fine Stonewashed pebbles. The curved cutting edge converges towards the needle-sharp tip of the knife. The thickness of the blade provides high strength while the high, flat grind gives excellent cutting edge geometry and extreme cutting performance. Ball bearings support the opening of the blade with either a dual thumb stud in the blade (dual thumb stud) or an oval hole (thumb hole). The entire blade is locked with what is considered to be the world's strongest Shark-Lock™ lock.

Handle - made of 6AL4V titanium with a slightly rough texture and CNC-machined pattern on the handle. Chamfered cover edges eliminate sharp edges for comfort, and a fore finger groove made on the front improves grip security. A single-position, right-handed clip allows the knife to be carried in the tip-up position, with the tip of the blade upward. A left-handed clip is included.

Technical data:

Product number: 205-20CV-TI-TEX-CP

Product name: AD20.5 Clip Point Milled Titanium, Stonewashed CPM 20CV

Overall length: 187.0 mm / 7.37″

Blade length: 76.2 mm / 3.0″

Blade thickness: 3.2 mm / 0.125″

Handle length: 114.0 mm / 4.5″

Handle thickness: n.d.

Weight: 115.0 g / 4.07 oz

Blade material: CPM 20CV

Blade hardness: n.d.

Blade grind: Flat

Blade finish: Stonewash

Handle material: Titanium 6AL4V

Handle finish color: Gray

Backspacer material: Stainless Steel

Backspacer color: Gray

Clip: Right, Tip-Up

Clip material: Stainless Steel

Pivot mechanism: Ball Bearing (ball bearings)

Locking mechanism: Shark-Lock™

Opening method: Manual, dual thumb stud, thumb hole

Additional accessories: Left-handed clip

Designer: Andrew Demko

Brand: Demko

Manufacturer: Demko Knives

Country of origin: Taiwan

Developed by: the Sharg® company